Highly Coupled ZnO/Quartz Structure Surface Acoustic Wave Device with Good Temperature Characteristics

The following materials are known for making good TCF radio frequency SAW filters - quartz, Li2B4O7, langasite, ZnO/quartz, SiO2 film/LiNbO3, SiO2 film/LiTaO3, SiO2 film/high density electrode/LiNbO3, SiO2 film/high density electrode/LiTaO3, etc. The frequency of MediaFLOTM in the USA is between 716.5 and 721.5MHz with a relative bandwidth of about 0.7%, which is small. Therefore, the electro-mechanical coupling coefficients (k2) of quartz, Li2B4O7, langasite and SiO2 film/LiNbO3 are not suitable for the application. Materials with suitable k2 and having good temperature characteristics may be ZnO/IDT/quartz structure or SiO2/high density electrode/LiTaO3. The k2 of the former is smaller than the desired value, and TCF and k2 of the latter may be a little different from the desired values, but there is a possibility of overcoming such differences through optimization of the film thickness of ZnO and/or SiO2, IDT electrode material, and/or the cut angle of quartz and/or LiTaO3. Under such circumstances, the research team decided to study the former ZnO/IDT/quartz structure.

It has been reported that a transversal type SAW filter has a good TCF and relatively large k2 which can be obtained through combining a quartz substrate having a cut angle with a positive TCF and a ZnO film having a negative TCF. However, this structure has a small reflection coefficient, thereby making it unsuitable for a resonator type device. For a narrow bandwidth RF filter application, which is the aim of the research team, a structure is necessary which has a little larger k2 and an optimum reflection coefficient, while still maintaining a good TCF value.

Figure 1 shows the calculated and measured k2 value of the ZnO film thickness dependence of the ZnO film/quartz structure. In the ZnO film/IDT/quartz structure and short-circuit electrode/ZnO film/IDT/quartz structure, k2 increases as the ZnO film thickness increases, reaching its peak in the range between 0.45λ and 0.5λ. These results prompted the research team to discuss optimization of the structure of the electrode material, electrode film thickness, ZnO film thickness, cut angle of quartz substrate, and the like, by targeting the range near 0.45λ to 0.5λ for ZnO film thickness while taking into account TCF≒0 and the reflection coefficient.

In order to use a multi-mode resonator filter in designing, an IDT requires a corresponding reflection coefficient, and electrode materials have to be reevaluated.

Fig. 1 ZnO film thickness dependence on electro-mechanical coupling coefficient in ZnO film/quartz structure

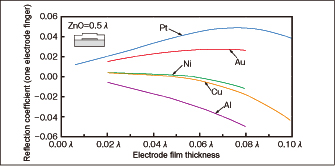

Figure 2 shows the relationship obtained from the calculation by the finite element method (FEM) between electrode film thickness and the reflection coefficient using Al, Cu, Ni, Au, and Pt for IDT electrodes in a ZnO/IDT/27ºY-X quartz structure. Within the range illustrated, Al always had negative reflection coefficients, and as the electrode film thickness increased, the absolute value of the reflection coefficient likewise increased. On the other hand, with Cu and Ni the electrode film thickness became zero in the range between 0.05λ and 0.06λ and near this range, sufficient reflection coefficients were not achievable. Au and Pt always had positive reflection coefficients, and the value also increased in the range between 0.02λ and 0.07λ.

Fig. 2 Relationships between electrode film thickness and reflection coefficient in ZnO/various electrodes/27ºY-X quartz structure