Murata Manufacturing Co., Ltd. (Head Office: Nagaokakyo-shi, Kyoto; Chairman of the Board and President: Tsuneo Murata; hereunder “Murata”) and the Research Institute for Light-induced Acceleration System (Director: Takuya Iida; Deputy Director: Shiho Tokonami; hereafter referred to as RILACS) at Osaka Prefecture University (Sakai-shi, Osaka; President: Masahiro Tatsumisago) have jointly developed a portable optical condensation system that employs RILACS’ optical condensation technology in a casing the size of a smartphone (Dimensions: length 10cm, width 6cm, depth 2cm).

This new technology will soon be exhibited at the .

The cultivation method, a common way of detecting bacteria, can require one or several days before a sufficient sample can be obtained. When checking for harmful germs like O157 in environments such as food processing in factories, or bacteria testing in labs and hospitals, conventional methods can take a long time and can be problematic. Furthermore, testing with traditional optical condensation systems require large equipment (typical dimensions: length 87 cm, width 67 cm, depth 72 cm), these systems can be difficult to transport. However with Murata`s miniaturization capabilities, as well as RILACS`s optical condensation technology, we have achieved a considerably smaller, portable device that will greatly reduce measuring times when testing for bacteria.

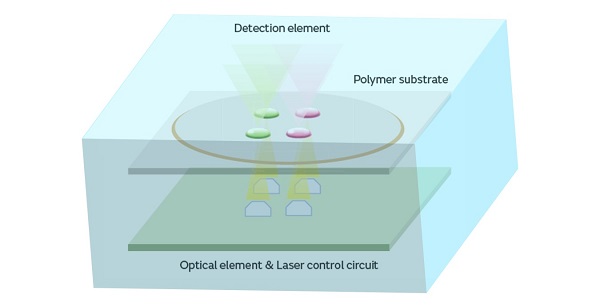

Structural diagram of the product

Features:

・ Small size (length 10cm, width 6cm, depth 2cm)

・ Uses RILACS’ optical condensation technology to physically condense samples and accelerate and control biochemical reactions

・ Portable detection system; this unique optical design utilizes Murata`s miniaturization capabilities

・ Greatly reduces the time required for bacteria testing,

・ Increased measurement sensitivity*1

・ Reduced testing time; compared to cultivation testing, optical condensation testing reduces testing time to 1/300*2.

*1 Using one element and 300 seconds of laser irradiation, the product traps more than 100,000 bacteria or minute particles; the element can also be turned into an array.

*2 Compared to testing that requires 24 hours, this system completes measurement within five minutes.

In modern times, as people and things travel more, improving the efficiency of health testing has become an urgent social problem and testing at hospitals and laboratories can often take several weeks. This new technology not only accelerates testing for bacteria, but we believe it can be applied to a variety of situations and applications. Due to its portability, it can support a number of demanding situations such as the prevention of bioterrorism, for detecting harmful bacteria or viruses that may be present in public areas. Both Murata and RILACS will continue to apply the expertise of academia and industry to produce technologies to solve today`s challenges for a better tomorrow.

Development Background and Additional Technological Information

The necessity of providing sufficient food for growing populations in the 21st century is an urgent problem for a sustainable society. Due to an increase in exports and imports in recent years, bacteria testing technology is essential for guaranteeing food safety. In healthcare environments, it is also necessary to swiftly detect bacteria that can lead to in-hospital infections, thus requiring the development of rapid and highly sensitive detection methods for bacteria.

Conventional bacteria testing relies primarily on the cultivation method. This method not only requires between one to ten days to obtain results, but also the handling of the growth medium and sterilization procedures can also be complicated. This has created a demand for more refined knowhow and technology to solve these challenges.

Methods have been developed in recent years to resolve these issues, these include; (ELISA) method*3 - an enzyme-linked immuno-sorbent assay, and a method that indirectly tests for the presence of bacteria by detecting adenosine triphosphate (ATP) an energy source for lifeforms. However, until now there has not been testing method that is operable from a compact device, and can induce bacteria at a measuring site, or test with high speed and with high sensitivity. The Optical tweezer technology was awarded the Nobel Prize in Physics in 2018, but because the operational range is about the same as the diameter of a laser spot of several micrometers, it only proved useful for precision measurements of small quantities of cells, subsequently it was difficult to quickly trap large quantities.

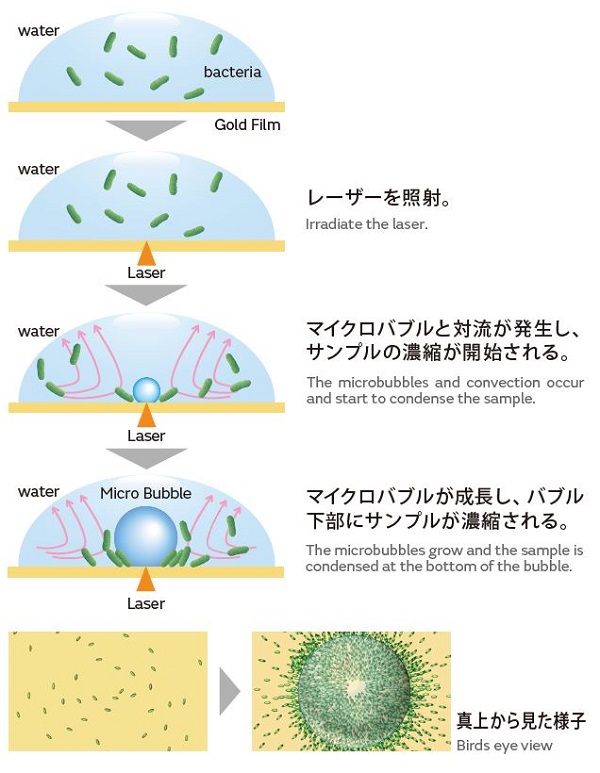

The technology works by causing microbubbles and convection heating within a liquid sample. This occurs due to the laser-generated heat from the optical system and substrate structure. This accomplishes an operational range of several millimeters, and works by inducing, condensing, and densely accumulating nano and micro particles to approximately 1.8 times higher than a conventional large-size device (Fig. 1).

Fig. 1. Conceptual diagram of the basic optical condensation mechanism

*3 The Enzyme-Linked Immuno-Sorbent Assay, or ELISA, method uses reactions of antigens and antibodies with high specificities to primarily detect and quantify the density of antibodies or antigens contained in liquid samples. The method uses the coloration and luminescence resulting from enzyme reactions as signals and requires various preprocessing, often demanding specialized knowledge and technology.

QUOTE: RILACS Director Takuya Iida (Associate Professor, Graduate School of Science)

Working with Murata we succeeded in miniaturizing a portable optical condensation system as the foundation of RILACS’ light-induced acceleration system of biochemical reactions. This product is about the same size as a smartphone and easy to carry around, which will make it a breakthrough in accomplishing rapid and highly-sensitive on-site health testing, responding for example to the food and beverage industry and enabling households to test the safety of their food. We expect that in the future the product will be further developed for minimally invasive healthcare testing that does not burden patients when testing for various biological samples in addition to bacteria and fine particles (such as DNA, allergens, proteins responsible for various illnesses, viruses, and carcinogenic material).

About RILACS at Osaka Prefecture University

RILACS is an interdisciplinary research institute with the aim to contribute to solving various social problems such as food testing, clinical testing, pharmaceutical development, environmental technologies, and energy conversion by globally pioneering and advancing research and development of a light-induced acceleration system (LAC-SYS) that measures and controls a diverse range of biochemical reactions remotely and non-destructively through optical condensation that exploits flows generated by the “optical force” and “heat of light”.

RILACS was founded in May 2017 as one of the “secondary research laboratories” under the management of the president of Osaka Prefecture University to implement strategic survey and research tasks within the framework of the LAC-SYS Project (“A Future Created by Next-Generation Biophotonics”), one of Osaka Prefecture University’s Key Projects*4 (see ).

*4 Key Projects consist of research selected by the president and given the necessary support for advancing each project. These projects are both cutting-edge and at the top of their fields globally, and may become the future face of Osaka Prefecture University.

About Murata Manufacturing

Murata Manufacturing is a global comprehensive electronic parts manufacturer engaged in the development, production, and sale of electronic components based on ceramics. It continues to contribute to the development of an electronic society through its material development, process development, product design, and production technology developed and refined in-house, and by generating creative products based on its technological foundation of software, analysis, evaluation, etc. that supports all of the above.

About the Joint Research between RILACS and Murata Manufacturing

RILACS and Murata Manufacturing began joint research on the development of a portable light-induced acceleration system in October 2017 and are vigorously advancing research and development for its practical application. Parts of the project’s results have been presented on at academic conferences and have resulted in patent applications.

- “Analysis of Light-induced Sets Using a Small Laser Light Source,” presentation draft collection of the 80th JSAP Autumn Meeting 2019, 18p-E204-15; Taichi Suehiro 1,2,3, Kenji Sakurai 2,3, Tsutomu Yamasaki 4, Hiroki Ishikawa 4, Mamoru Tamura 1,3, Shiho Tokonami 2,3, Takuya Iida 1,3 (1. Graduate School of Science, Osaka Prefecture University, 2. Graduate School of Engineering, Osaka Prefecture University, 3. Research Institute for LAC-SYS, Osaka Prefecture University, 4. Murata Manufacturing Co., Ltd.) (September 18-21, 2019, Hokkaido University, Sapporo Campus)

- Two patents pending

Research Funding, etc.

This research was primarily carried out and completed as part of the project of , “Development of a minimally invasive high-throughput optical condensation system (research and development representative: Takuya Iida, joint researchers: Shiho Tokonami, Ikuhiko Nakase)” (JPMJMI18GA) in the “Common Platform Technology, Facilities, and Equipment” Area of the JST-Mirai Program from Japan Science and Technology Agency (JST), and was also supported by Grant-in-Aid for Scientific Research (A) (JP17H00856), Grant-in-Aid for Scientific Research (B) (JP18H03522), Scientific Research in Innovative Areas (proposal) “Nano-Material Manipulation and Structural Order Control with Optical Forces” (area representative: Hajime Ishihara) (JP16H06507) from the Japan Society for the Promotion of Science (JSPS), the Murata Science Foundation, Osaka Prefecture University Key Projects, and other sources.

The research grant (for natural science) from Murata Science Foundation in fiscal 2018 supported the research subject “High-speed external-field-induced biosensor based on micro-pores with molecular recognition ability”.