10/5/2023

Murata Manufacturing Co., Ltd.

President: Norio Nakajima

Murata Manufacturing Co., Ltd. (Head Office: Nagaokakyo-shi, Kyoto / President: Norio Nakajima) and Yasunaga Corporation (Head Office: Iga-shi, Mie / President & CEO: Akitoshi Yasunaga; hereinafter “Yasunaga”) have jointly developed a wick using a new material for vapor chamber heat dissipation components used in electronic equipment.

This wick is the first product jointly developed by Murata Manufacturing and Yasunaga. The product combines Murata’s small electronic component design expertise and Yasunaga’s outstanding micro-metalworking technologies. Our two companies will continue to strengthen our collaborative relationship in the future to make products to solve heat problems in next-generation devices.

Measures against heat have become essential due to the significant increase in data processing volume as a result of the higher performance, capacity, and speed of electronic equipment. There has been a particular need in recent years for smaller and thinner smartphones, wearable devices, and gaming PCs. That has led to vapor chambers being equipped as ultra-thin thermal diffusion devices capable of quickly diffusing localized heat generation in electronic equipment.

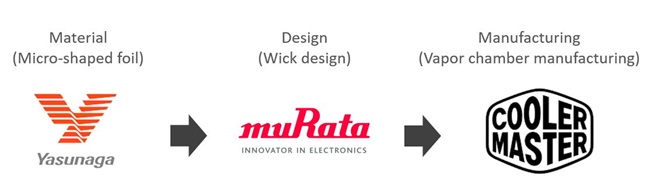

We have now developed a new wick by combining Murata Manufacturing’s design expertise with the micro-shaped foil independently developed by Yasunaga. Cooler Master Co., Ltd. will manufacture and sell vapor chambers equipped with this wick.

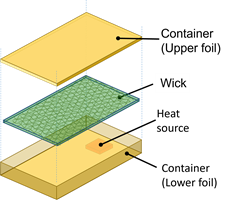

Vapor chamber structure and wick

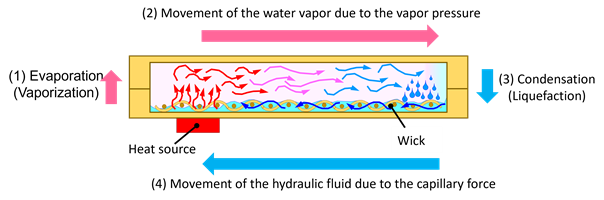

A vapor chamber is a thermal diffusion device that encloses a hydraulic fluid (water) and wick in a container pasted together with thin metal foil. The hydraulic fluid evaporates in response to the heat generated by the heat source. The vapor is then diffused in the vapor chamber to dissipate the heat. It has a structure that, when the heat is dissipated, the vapor condenses again as a liquid and circulates to the heat source again due to the wick, which has micro-gaps.

Until now, metal mesh and metal powder sintering were generally used to make wicks. However, we use micro-shaped foil independently developed by Yasunaga to make this new wick.

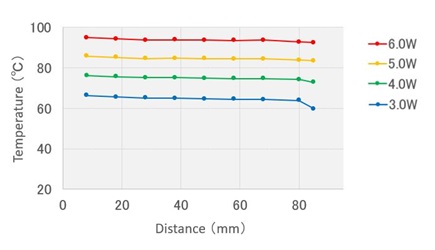

The figure below shows the performance when this new wick and a conventional wick (metal mesh) are inserted into a vapor chamber. The new wick has a capillary force several times that of the conventional wick. This enables a further improvement in performance and reduction in thickness of the vapor chamber.

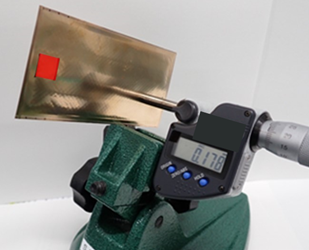

We have successfully developed an ultra-thin vapor chamber with a thickness of less than 200 μm as a result of using this new wick. Despite its ultra-thin structure, it achieves high heat uniformity with respect to the quantity of heat input required for smartphones.

Satoru Muto, General Manager of the New Business Incubation Department in Murata Manufacturing, said the following:

“We are able to provide an ultra-thin vapor chamber through Cooler Master Co., Ltd. by utilizing the micro-metalworking technologies possessed by Yasunaga in the wick design we have developed. The performance of electronic equipment will continue to become more sophisticated in the telecommunications market in the future. This means the necessity of heat dissipation solutions will continue to increase. We will realize a comfortable electronics society by further strengthening cooperation to provide heat solution products supported by powerful core technologies.”

Akitoshi Yasunaga, President & CEO of Yasunaga Corporation, said the following:

“I am sincerely happy to announce this joint development. Yasunaga has researched and developed micro-metalworking over a period of more than 10 years. We have nurtured our expertise in this area to the highest technological level in the world. We are now able to produce an innovative wick by combining the strengths of both of our companies. We will contribute to the richness of people’s lives by expanding the products essential for heat management in electronic equipment in the information society in the future.”

Murata in Brief

Murata Manufacturing Co., Ltd. is a worldwide leader in the design, manufacture and sale of ceramic-based passive electronic components & solutions, communication modules and power supply modules. Murata is committed to the development of advanced electronic materials and leading edge, multi-functional, high-density modules. The company has employees and manufacturing facilities throughout the world.

Yasunaga Corporation

Yasunaga is a manufacturer of engine components for automobiles, industrial machinery, construction machinery, agricultural machinery, marine equipment, and leisure equipment. It also develops, manufactures, and sells machinery such as machine tools, wire saws, and inspection and measurement systems. The company contributes to society with the technologies and services it has accumulated. In addition, it will continue to contribute to the richness of society and culture by proactively developing creative core technologies such as with micro-shaping and making market proposals for them.

Murata in Brief

Murata Manufacturing Co., Ltd. is a worldwide leader in the design, manufacture and sale of ceramic-based passive electronic components & solutions, communication modules and power supply modules. Murata is committed to the development of advanced electronic materials and leading edge, multi-functional, high-density modules. The company has employees and manufacturing facilities throughout the world.

For more information, visit Murata's website